Laser cutting

The designs that Olly chose were cut out of a darker coloured metal than the light aluminium of the case, to provide a two-tone effect. Laser cutting was essential to get the fine detailing that was required.

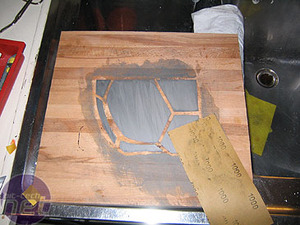

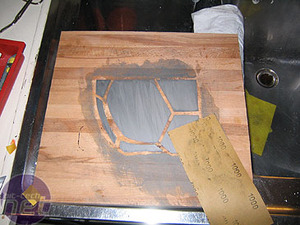

Before any of the designs could be fixed onto the case, they had to be polished and buffed first. "I sanded them down, first, with 600-grit and 100-grit sandpaper. When that was done, I pulled out my Dremel, fixed on a polishing wheel and broke out some polishing paste."

But how to get them to sit neatly on the side of the case? The answer is nothing fancy - just plain old craft glue. "A tip for you - don't use superglue! If you do, you won't be able to make any small corrections, because the glue will dry too fast. I used good old

Pattex Classic glue."

The end result turned out rather well. The accurate laser cutting means that the pieces that sit over the optical drive are all perfectly aligned. See what we mean about the two-tone effect?

Want to comment? Please log in.